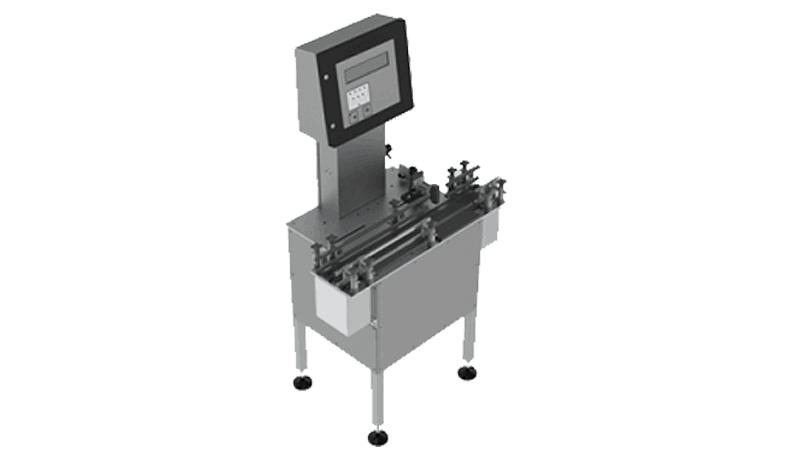

The Canalyzer MB is bottom only dud detector. This machine measures the deflection on one end of the can at high speeds. Our special high-frequency scanning technology allows the Canalyzer to accurately profile the can end over several hundred to several thousand data points. This scanning technology allows the Canalyzer to be able to detect a leaking can, even if there is minimal change between a good can and a leaking can.

The Canalyzer MB is bottom only dud detector. This machine measures the deflection on one end of the can at high speeds. Our special high-frequency scanning technology allows the Canalyzer to accurately profile the can end over several hundred to several thousand data points. This scanning technology allows the Canalyzer to be able to detect a leaking can, even if there is minimal change between a good can and a leaking can.

The Canalyzer MB is bottom only dud detector. This machine measures the deflection on one end of the can at high speeds. Our special high-frequency scanning technology allows the Canalyzer to accurately profile the can end over several hundred to several thousand data points. This scanning technology allows the Canalyzer to be able to detect a leaking can, even if there is minimal change between a good can and a leaking can.

- The Canalyzer MB has its own precision integrated conveyor for accurate inspections.

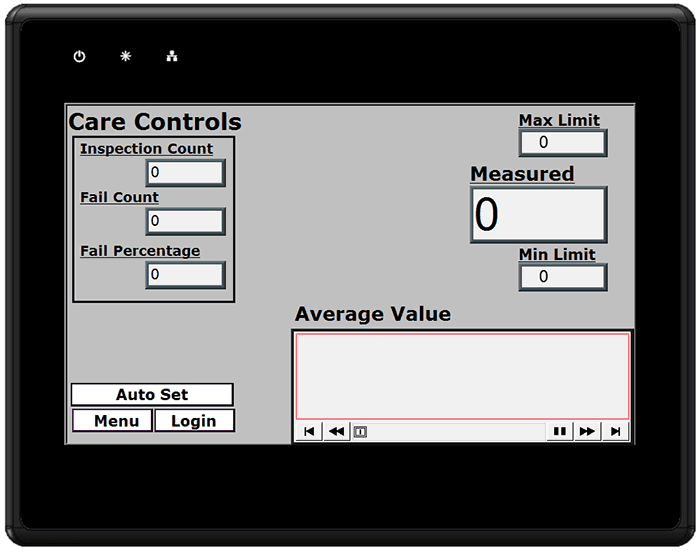

- Displayed measurements of 0.001inch can be compared to depth gauge reading for real world feedback.

- Tests one end of the can against independent control limits.

- SLC controls automatic selection of set points can be used to start a new code based on the standard deviation in seconds. Trending set points or percentage kick outs can also be maintained automatically.

- Precision sensor adjustments for accurate inspections and fast changeover times

- Inspects large variety of can types and sizes

- Wear parts are made from a static dissipating material to eliminate sensor interference.

| Operating Speed | 1200 (Standard)/ 1600 (High speed) inspections per minute max |

| Power Requirements | 100-250 VAC, 50 or 60 Hz single phase, isolated incoming power for Control 240-480 VAC 50 or 60 Hz three phase power for motor |

| Pneumatic Requirements | 35-50 psi; ¼” standard (Options available) |

| Spacing Requirements | Zero backline pressure from containers. Accumulation should stop 20 inches from discharge |

| Display | Touchscreen display |

| Operating Conditions | Stable Ambient Temperature: 32º to 122º F (0º - 50º C) |

| Communications | RS-232 report sending capability (optional) |

| Enclosure | Nema 12 std (Nema 4, IP 65 optional ) |

| Length | 40.0” Standard; conveyer extensions available (32.0”, 40.0”, 48.0”) |

| Height | 32.0” Standard +/- 2.0” (extensions available) |

| Eject | Pneumatic cylinder with soft bumper |

| Interface | Intuitive with multiple access levels, Touchscreen (HMI) interface |

| Construction | Stainless Steel, engineered plastics and Aluminium (Durable construction for the food and beverage industries) |